Banding tape thickness | 0.4-3 mm |

Banding tape width | 10-60 mm |

Work piece thickness | 10-60 mm |

Work piece length | >=100 mm |

Work piece width | >=50 mm |

Heating power | 1.5 KW |

Feeding motor power | 2.2 KW |

Glue spreading power | 0.37 KW |

End trimming power | 0.55 KW x 2 |

Fine trimming power | 0.75 KW x 2 |

Polishing motor power | 0.18 KW x 2 |

Feeding speed | 13 m/min |

Air pressure | 0.7 Mpa |

Total Power | 6.23 KW |

Overall dimension | 3600x900x1500 mm |

Packing size | 3670x1000x1600 mm |

N.W. | 1300 KGS |

G.W. | 1470 KGS |

We use large aluminum beam, very strong and work stably. The surface of our edge banding machine is milled, and the flatness is less than 0.1mm.

The glue pot is made of imported special ball bearing, high hardness and super wear-resistant material rubber box.

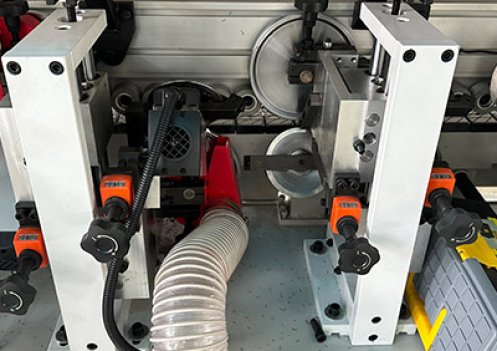

End trimming mechanism through a precise guide track movement, adopt automatic tracking and high frequency motor to ensure the cutting surface smoothly.

Fine trimming adopts automatic roll forming structure and high frequency high speed motor etc. to trim and process excess edging material at the top and bottom of the sheet edge.

Upgraded scrapping mechanism with larger drive and large copy wheel to remove the wavy marks caused by the non-linear motion cutting process of trimming.

The polishing device adopts the board processed by cotton polishing wheel, by end polishing to make a smoother surface.